Ningbo Daily News (Reporter Li Ping, Correspondents Tang Wenjun and Zhou Yanchi) A hardware processing factory in Yongkang, Zhejiang Province, which ordered more than 50 sets of industrial robotic arms from DZICS Company at the end of last year, has now put them into normal production. These industrial robotic arms are installed on 50 CNC machine tools in the factory, not only ensuring better product quality and production safety but also replacing a considerable number of front-line workers. "Previously, one worker operated one machine. After using the industrial robotic arms, one person can monitor more than 5 machines, reducing at least 20 front-line workers for this enterprise," said Dai Xiang, general manager of DZICS Industrial Robot Technology Co., Ltd., in a recent interview.

DZICS Company's robotic arms, independently developed over three years, have now entered a stable mass production phase, with an annual production capacity of 500 sets. These robotic arms applied to CNC machine tools can replace more than 230 workers. "The company is currently building an industrial robotic arm production project in Beilun Xiaogang Equipment Industrial Base, which will be operational the year after next. By then, it will have an annual production capacity of 2,000 sets of industrial robotic arms. When these 2,000 sets are deployed in client enterprises, they can replace at least nearly a thousand front-line workers," Dai Xiang said.

While alleviating labor shortage issues, DZICS Company's annual production of industrial robotic arms also brings significant economic benefits to client enterprises. "According to estimates, the annual cost of employing one skilled worker, including salary, benefits, and various social insurances, exceeds 70,000 yuan. Just by replacing 230 workers, client enterprises can save more than 10 million yuan annually in expenses. The reduction in front-line staff will correspondingly decrease management personnel and expenses, as well as production and living support costs. Comprehensive estimates show that these 500 sets of industrial robotic arms can help client enterprises reduce costs by more than 20 million yuan annually, greatly enhancing their market competitiveness," Dai Xiang explained.

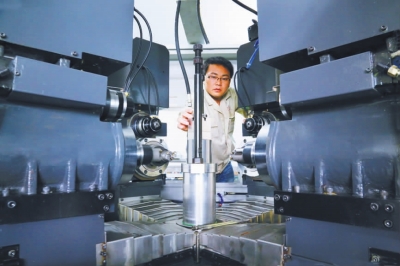

At DZICS Company's automotive instrument assembly robotic arm developed for Zhejiang Automotive Instrument Company, the reporter observed: The robotic arm uses high-resolution industrial cameras to precisely capture targets and integrates instrument control and initialization modules. It can not only automatically identify, judge, grasp, and assemble pointers with a diameter of only 1 millimeter but also inspect whether components are installed accurately. If quality issues are detected, it immediately issues warnings. "One such robotic arm can replace five or six workers. Using robotic arms isn't just about replacing humans with machines; it also transforms the daily work state of workshop workers. Production operations and speed are controlled by the robotic arms, while front-line workers shift from on-site operations to quality inspection and equipment maintenance. The use of industrial robotic arms also significantly reduces the probability of workplace injuries and effectively eliminates human errors and inconsistencies in operations," said Wang Lu, DZICS Company's on-site manager.

Currently, DZICS Company is accelerating the development of new products to meet the needs of more machinery processing enterprises for machine replacement. The company's newly developed mobile robotic arms have higher automation levels, enabling one person to manage 10 machine tools, with feeding accuracy improved to 0.05 millimeters. It's estimated that 300 units will be sold this year.